Foil Stamping and Embossing

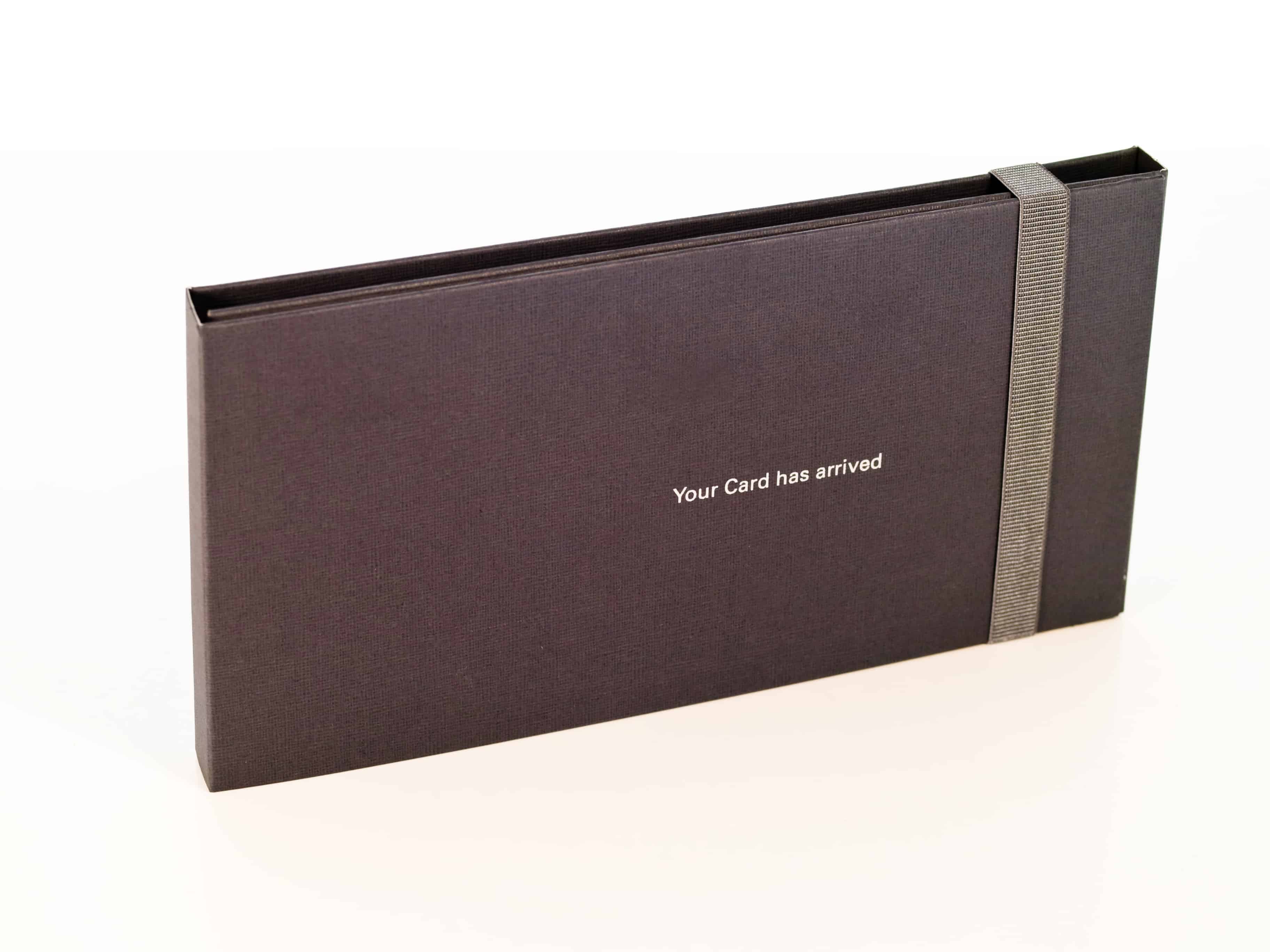

Globe's foil stamping process applies a metallic or pigmented foil to a surface creating a decorative finish.

The foil stamping process utilizes metal dies, which when combined with heat and pressure, permanently bond a thin foil film to a surface. Foil stamping can be used to achieve a variety of specialized textures, including matte, metallic, glossy, and holographic finishes. The die is heated up, and a thin layer of foil is placed between the die and the substrate. The die then applies pressure to the foil and the printing surface, causing the foil to permanently bond to the surface in the shape of the plated design.

For multiple colored designs, separate dies need to be created for each color, and several runs of the press foiling machine are required to produce the final design. Special effects such as embossing or raising may be achieved through the use of another specialized die.

Production Capabilities

One automatic stamping press, sheet size up to 36″x 49″

Embossing up to 40″ x 56″ sheet size

Three additional presses for small or large formats